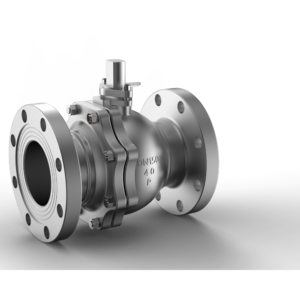

a. The valve body structure is integrally welded and there will be no external leakage.

b. The valve seat is composed of a PTFE sealing ring and spring, which has strong adaptability to pressure and temperature changes and will not cause any leakage within the range of use.

c. The anti-leakage structure of the valve stem has a PTFE self-sealing gasket and an O-ring at the bottom of the valve stem, and there are 2 O-rings and two PTFE gaskets on the top to ensure no leakage.

d. The valve body material is the same as the pipe material, so there will be no uneven stress and no extrusion and deformation due to earthquakes and vehicles passing over the ground.

e. The valve body is light and easy to keep warm.

f. Directly buried ball valves can be buried directly underground. There is no need to build tall valve wells. Instead, only small shallow wells need to be set up on the ground, which greatly saves construction costs and engineering time.

g. The length of the valve body and the height of the valve stem can be adjusted according to the construction and design requirements of the pipeline.

h. The processing accuracy of the sphere is very precise and the operation is light, without any adverse interference.

i. There are two connection methods: welding and flange.

j. Operation mode: handle, gear (vertical/horizontal)

k. Under normal operation and use of the valve, the warranty period is 20 years.

Steel reduced diameter welded ball valve

Welded ball valves are widely used in various fields. Their superior quality and high-performance stability are beyond the reach of ordinary cast steel ball valves. The service life of fully welded ball valves is much longer than that of cast steel ball valves. Fully welded ball valves are widely used in city gas, urban heating, petrochemical industry, shipbuilding, steel, voltage regulating stations, power plants, and other types of pipeline equipment.

- Description